Here at Opus Plastics, we are injection moulding and extrusion specialists with over 35 years of proven and tested experience in the field of plastic manufacturing. As such, we’ve learnt all about the necessary prerequisites for delivering high-quality extrusion design for customers in a variety of industries. From the intricacies of the finer details to dedicating enough time at the start of the project to ensure desirable results, we’ve put together just seven of the factors we think make for the best standard of extrusion design.

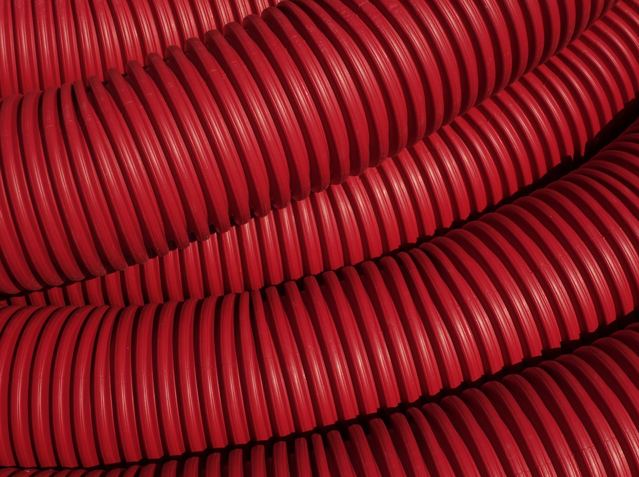

What is Tube Extrusion?

Here at Opus Plastics, we love to teach people all about the efficient plastic manufacturing services that we offer, including how it could revolutionise the way in which your business operates today. Many will opt for more expensive alternatives because of a lack of education on other potential methods or an unfounded negative view on the plastics industry. We use our blog as a space to show you exactly what we do and why, so you can read up on various processes before deciding what’s right for you and your company. Today, we are looking at tube extrusion, so read on to find out everything you need to know about how it works, what we do and why!