There are a number of factors to consider when selecting the material to use for your plastic extrusion design. Plastic extrusion products will be custom made to order, so the right plastic type will be selected to fit your specific requirements or needs. Selecting the right material for the project will ensure that your design works as it is intended, as well as allowing you to have a more cost-efficient product. As such, it will be important to disclose your exact purposes for the product and all that you will expect from it when in the design stage of the process. Here are some of the factors that you should be considering when looking for a plastic extrusion quote: Continue reading “How to Select the Best Material for Your Plastic Extrusion Design”

7 Factors for Quality Extrusion

Here at Opus Plastics, we are injection moulding and extrusion specialists with over 35 years of proven and tested experience in the field of plastic manufacturing. As such, we’ve learnt all about the necessary prerequisites for delivering high-quality extrusion design for customers in a variety of industries. From the intricacies of the finer details to dedicating enough time at the start of the project to ensure desirable results, we’ve put together just seven of the factors we think make for the best standard of extrusion design.

What is Liquid Injection Moulding?

When it comes to the manufacturing of plastic, there’s several different processes that are suitable for various client requirements. In recent blogs, we’ve look at both plastic and tube extrusion and how we use it to create cost-efficient, high-quality products for our brilliant customers. This week, we’re looking at liquid injection moulding, what it is, why it’s used and how the machines work, alongside the various considerations that need to be taken into account when deciding upon the process that’s best for you. Continue reading “What is Liquid Injection Moulding?”

A Guide to Thermoplastics

Although plastics are used in most areas of our lives, many of us will not know the difference between the many varieties of plastics that are available. While there are many different types of plastic, with many different uses, by far the most commonly used form of plastic is thermoplastic. Our guide to thermoplastics should help you understand more about this essential type of plastic! Continue reading “A Guide to Thermoplastics”

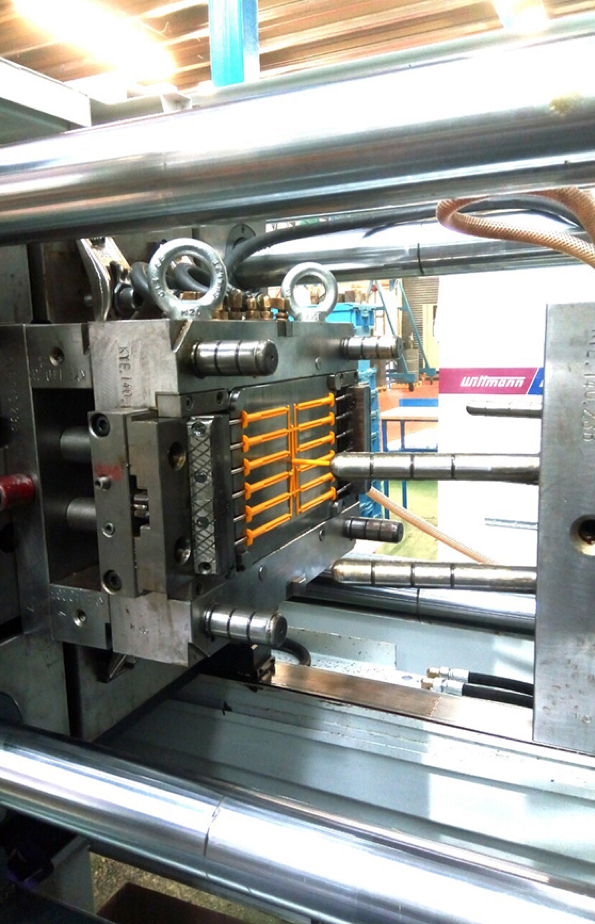

How Does an Injection Moulding Machine Work?

Injection moulding is one of the most cost-effective, popular and efficient manufacturing processes available and is responsible for a large number of the products you use every day – but how exactly does it work? Here at Opus Plastics, we are passionate about what we do and like to shout about the capabilities of our shiny, clever machines whenever we can. Whether you’ve heard of it before or not, you work in the industry or you’re just interested, we’ve put together a guide to outline exactly how an injection moulding machines works.

Continue reading “How Does an Injection Moulding Machine Work?”

What is Mould Flow Analysis?

Here at Opus Plastics, we utilise the latest plastic manufacturing techniques to create high-quality products via extrusion moulding for a range of industries. However, before the plastics are created through our efficient machines, a lot of planning goes into how we can produce such a fantastic end result for our clients. This blog will focus on mould flow analysis to look at the first stage of the production process and we go about beginning the complex journey of manufacturing your products.

What Is Plastic and How Are Plastics Made?

Plastics are all around us and play a part in almost every aspect of our lives. Despite this, we don’t always consider where they come from and some may not even know how they are made. Knowing how plastics are created can help us to understand this material’s full potential and how it can be used to suit the needs of businesses and consumers.

Continue reading “What Is Plastic and How Are Plastics Made?”