There are a number of factors to consider when selecting the material to use for your plastic extrusion design. Plastic extrusion products will be custom made to order, so the right plastic type will be selected to fit your specific requirements or needs. Selecting the right material for the project will ensure that your design works as it is intended, as well as allowing you to have a more cost-efficient product. As such, it will be important to disclose your exact purposes for the product and all that you will expect from it when in the design stage of the process. Here are some of the factors that you should be considering when looking for a plastic extrusion quote: Continue reading “How to Select the Best Material for Your Plastic Extrusion Design”

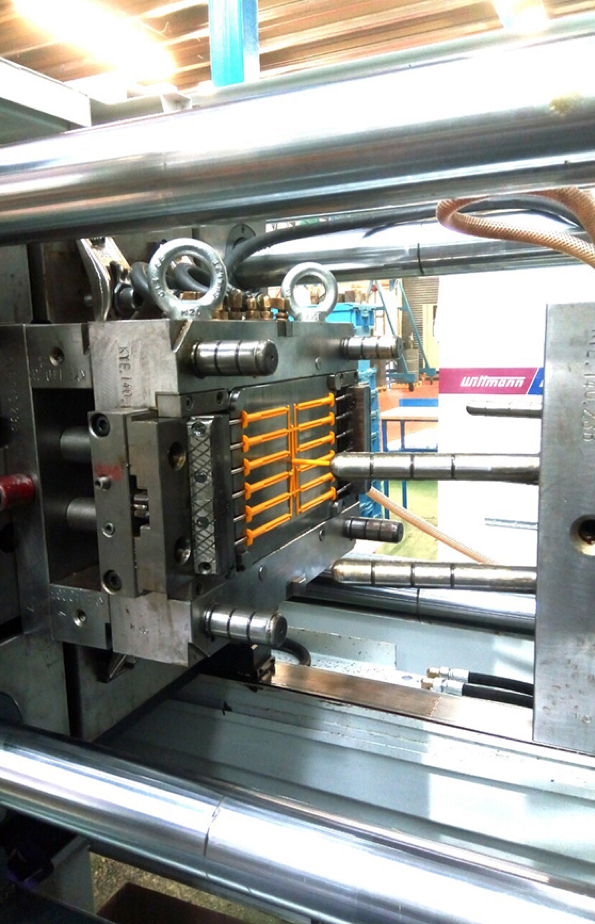

What is Mould Flow Analysis?

Here at Opus Plastics, we utilise the latest plastic manufacturing techniques to create high-quality products via extrusion moulding for a range of industries. However, before the plastics are created through our efficient machines, a lot of planning goes into how we can produce such a fantastic end result for our clients. This blog will focus on mould flow analysis to look at the first stage of the production process and we go about beginning the complex journey of manufacturing your products.

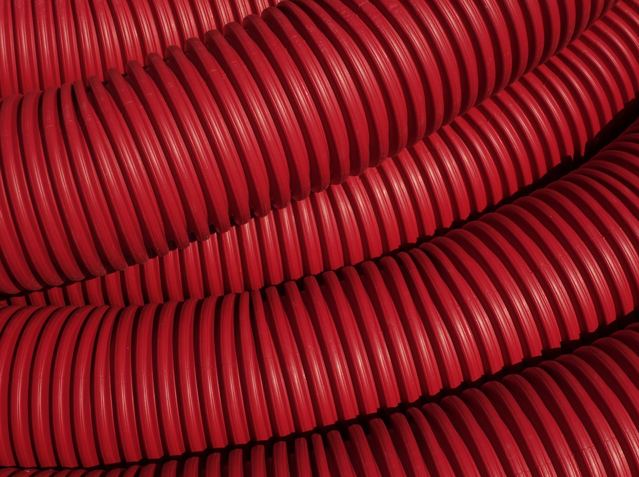

What is Tube Extrusion?

Here at Opus Plastics, we love to teach people all about the efficient plastic manufacturing services that we offer, including how it could revolutionise the way in which your business operates today. Many will opt for more expensive alternatives because of a lack of education on other potential methods or an unfounded negative view on the plastics industry. We use our blog as a space to show you exactly what we do and why, so you can read up on various processes before deciding what’s right for you and your company. Today, we are looking at tube extrusion, so read on to find out everything you need to know about how it works, what we do and why!